Allcontrols supplies bespoke turnkey solutions for automated polyethylene terephthalate (PET) recycling lines, with the ability to remove PVC, PET-G, fibres, metals and non-conforming colours, achieving purities of less than 50ppm contamination in the PET stream.

PET is one of the most commonly used plastic types and dominates the packaging market for consumer goods. It is used in a huge range of manufactured products including drinks bottles, jars and containers, household cleaning materials and pharmaceutical products. An estimated 41.56 million tonnes of PET was produced globally in 2014. By 2020 the forecast was set to rise to 73.39 million tonnes.

Allcontrols offers the latest state-of-the-art sorting and separation technology to meet all commercial requirements for PET recycling, utilising its extensive experience to design, install and manage a wide range of bespoke solutions.

Material sorting and separation solutions available from Allcontrols include:

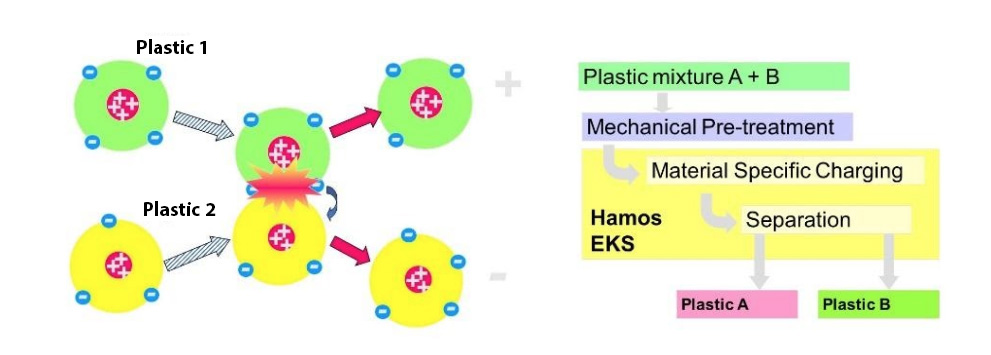

The EKS electrostatic separator

This can separate PVC, PET-G and fibres from PET into very high purity fractions. The different polymer types are charged by impact in the Hamos EKS system. The impact causes one polymer type to lose electrons and the other polymer type to adopt them, resulting in positively and negatively charged polymer fractions.

The charged polymer fractions are now transported to a high-voltage field that is either negative or positive. Depending on the charge, the polymer fractions are either attracted or pushed away by the high-voltage field.

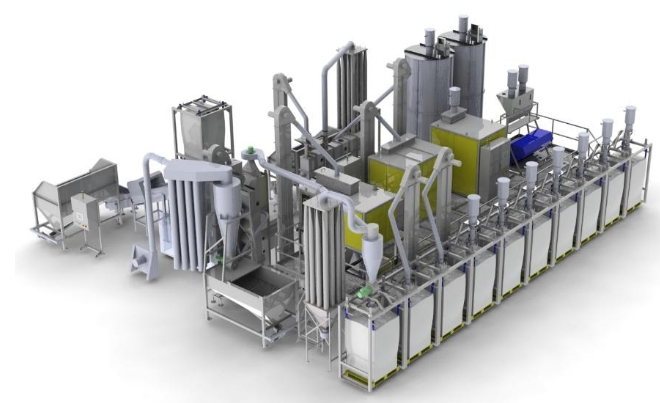

Example of Hamos electrostatic separation plant.

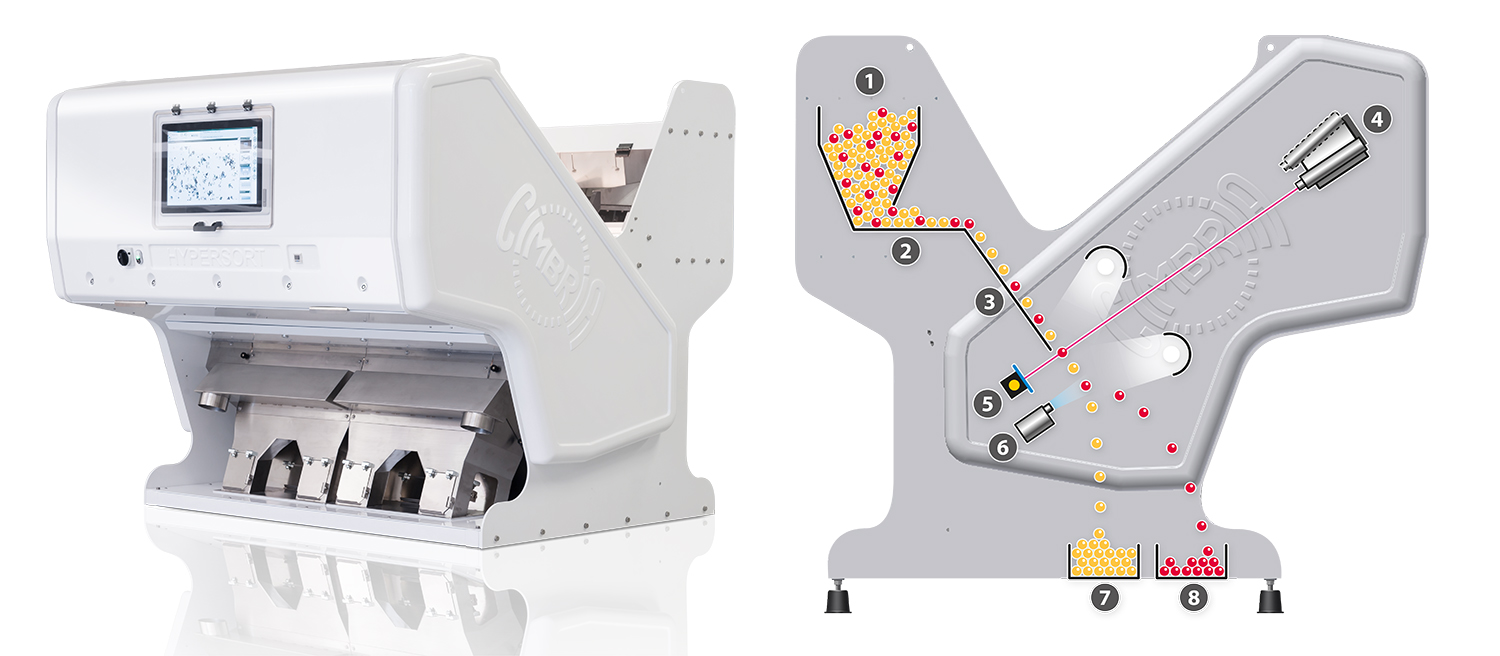

The SEA.HY

This offers the unique option to sort granulate/flake polymer types and colour in real time. Polymers – including PET, PVC, PE, PP, PS, HDPE and many more – can be separated into high-purity fractions. The SEA.HY uses hyperspectral near-infrared sensors, which can identify different polymers even if they have the same colour, thus enabling polymer flakes to be separated according to their chemical nature. The SEA.HY can sort fraction sizes of between 2mm to 50mm. Two types of SEA.HY are available – standard or high resolution – depending on the applications required.

OPERATION

1 Infeed hopper

2 Vibratory feeder

3 Material chute

4 Hyperspectral and optical systems

5 Lighting and background

6 Ejectors

7 Accept fraction

8 Ejected fraction

The SEA.CX Optical Sorter

This is equipped with high-resolution full-colour RGB trichromatic cameras, combined with an HSI software system that allows near-human eye vision capability to sort precisely almost any small shade differences. The SEA.CX is available with up to seven chutes and can be configured for re-sort operation in real time. User-friendly software programming enables ease of operation, which can be adjusted to allow real-image setting directly onto the sorter touch-screen. This enables the defective elements to be channelled away from the required elements. As well as the two RGB cameras per channel, the SEA.CX can be equipped with two additional cameras (NIR, InGaAs).

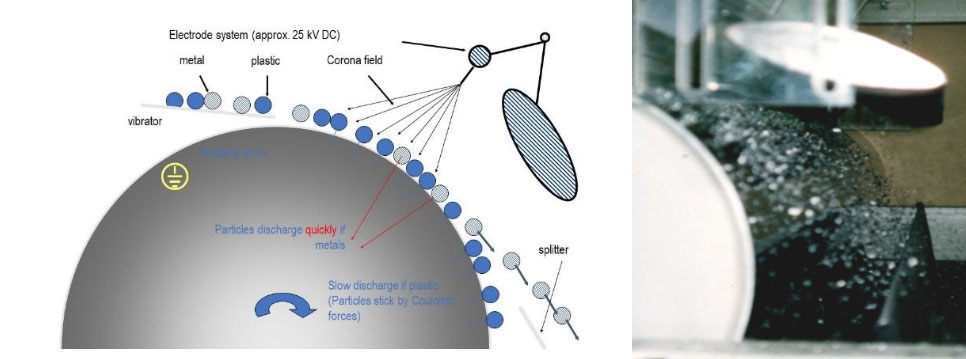

The KWS electrostatic metal/plastic separator

The Hamos KWS Electrostatic Separator can separate conductive and non-conductive fractions because of the differences in conductivity and de-charging characteristics of metal and plastic materials. The Hamos KWS can separate particles of up to 10mm in size.

All particles get charged by a corona (high-voltage) field and positioned on an earthed drum where discharging takes place.

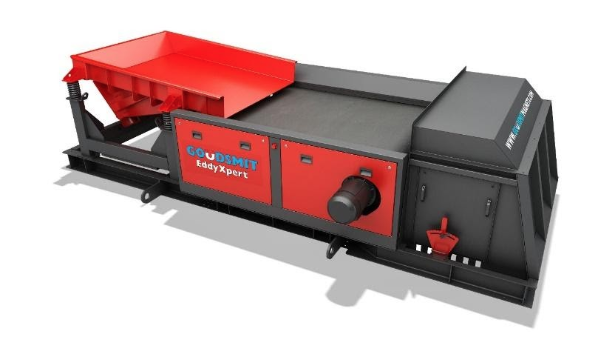

Eddy Current Separators

The range of Goudsmit eccentric eddy current separators, with up to 950 pole-changes per second, can separate even the finest non-ferrous fractions (>0.5mm) from the product stream, without the risk of rotor burn-in.

If you would like more information or want to speak to a member of our team, please email us on sales@allcontrols.co.uk or call our office on 01223 223900 and we would be happy to discuss your requirements.