Allcontrols engineers a unique range of sorting technologies for PE and PP that can meet most commercial recycling and recovery needs – even allowing black polymers to be separated during the sorting process.

PE is one of the most common plastics used around the world, with around 80 million tonnes produced each year. PE is manufactured in different densities, including HDPE and LDPE forms. With similar physical properties to PE, PP is another common type of polymer. Approximately 45 million tonnes are produced annually, and this is predicted to increase to around 62 million tonnes by 2020. Both PE and PP are extremely versatile materials, and are used for packaging such as bags, plastic films and bottle tops. PP is also used in a wide number of automotive industry applications, including in bumpers, side panels and cable wire insulation. Allcontrols’ specialist sorting and separation solutions – including tribo-electric separators and optical sorters –enables a profitable way of separating rigid PP and PE mixtures into high-purity fractions. Material sorting and separation solutions available from Allcontrols include:The EKS electrostatic separator

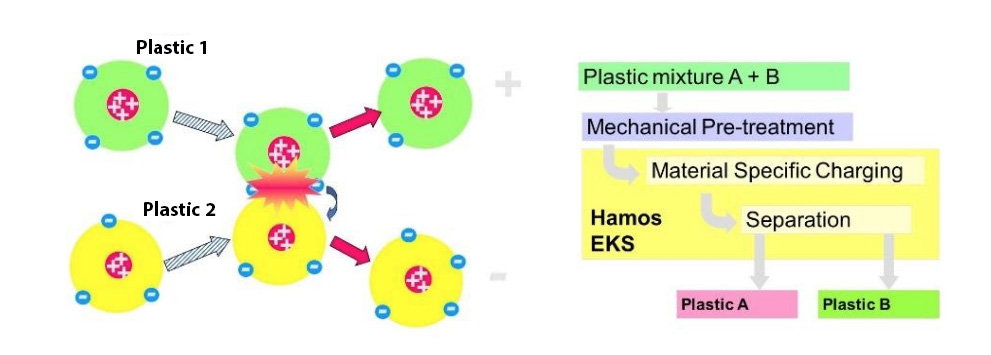

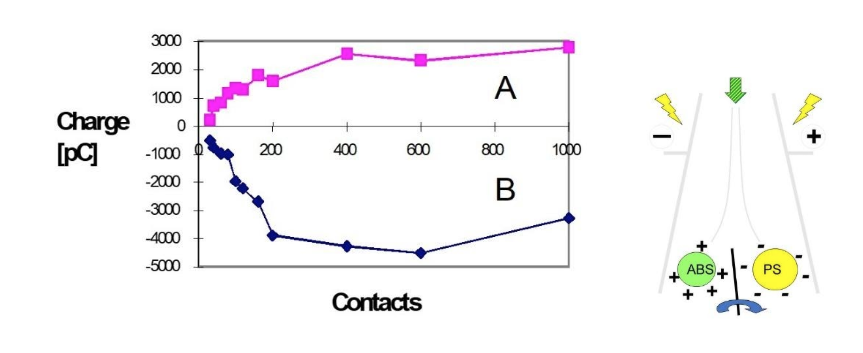

This can split co-mingled granulated polymers (including black plastics) into very high purity fractions. The different polymer types are charged by impact in the Hamos EKS system. The impact causes one polymer type to lose electrons and the other polymer type to adopt them, resulting in positively and negatively charged polymer fractions. The charged polymer fractions are now transported to a high-voltage field that is either negative or positive. Depending on the charge, the polymer fractions are either attracted or pushed away by the high-voltage field.

The charged polymer fractions are now transported to a high-voltage field that is either negative or positive. Depending on the charge, the polymer fractions are either attracted or pushed away by the high-voltage field.

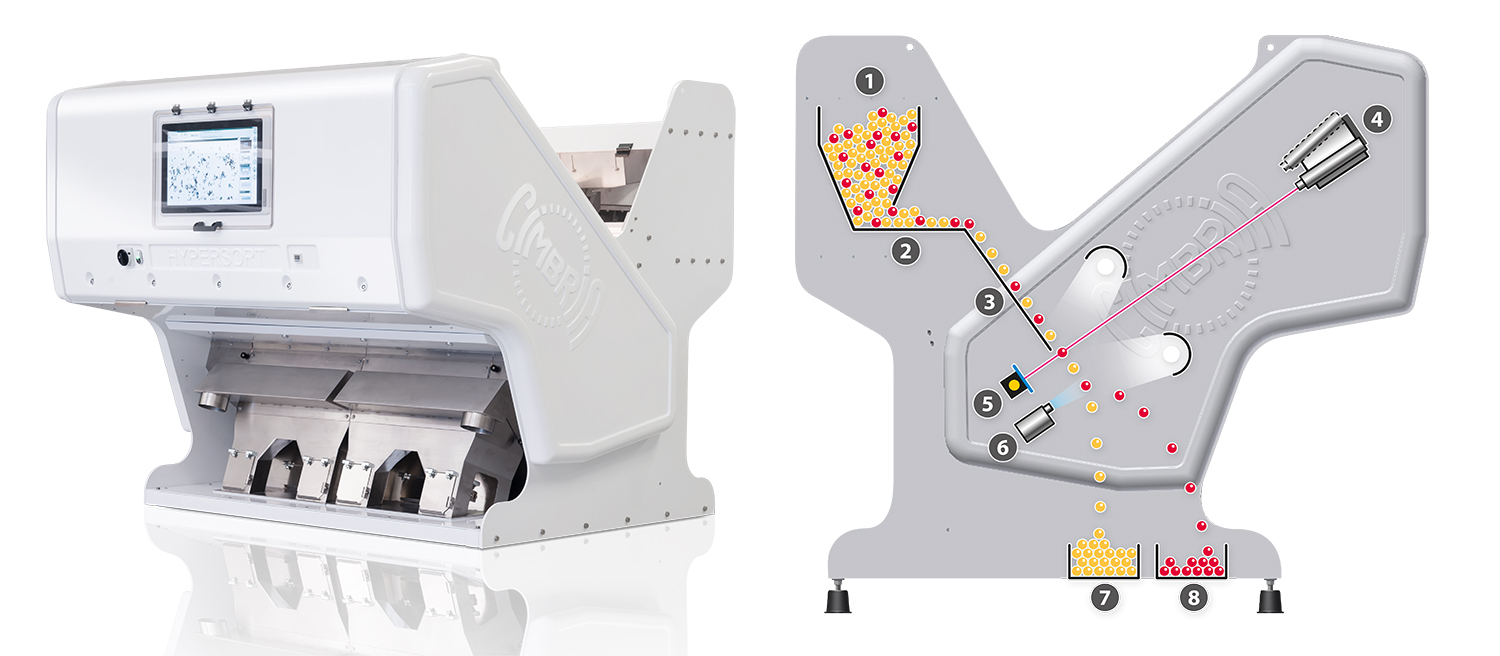

The SEA.HY

This offers the unique option to sort granulate/flake polymer types and colour in real time. Polymers – including PET, PVC, PE, PP, PS, HDPE and many more – can be separated into high-purity fractions. The SEA.HY uses hyperspectral near-infrared sensors, which can identify different polymers even if they have the same colour, thus enabling polymer flakes to be separated according to their chemical nature. The SEA.HY can sort fraction sizes of between 2mm to 50mm. Two types of SEA.HY are available – standard or high resolution – depending on the applications required. OPERATION

1 Infeed hopper

2 Vibratory feeder

3 Material chute

4 Hyperspectral and optical systems

5 Lighting and background

6 Ejectors

7 Accept fraction

8 Ejected fractions

OPERATION

1 Infeed hopper

2 Vibratory feeder

3 Material chute

4 Hyperspectral and optical systems

5 Lighting and background

6 Ejectors

7 Accept fraction

8 Ejected fractions If you would like more information or want to speak to a member of our team, please email us on sales@allcontrols.co.uk or call our office on 01223 223900 and we would be happy to discuss your requirements.